Ceramir CAD/CAM i-BLOCK Implant (ø L) Chroma Shade A2 12x14x18mm 5pcs/box

- Product Code: 805200

- Availability: In Stock

-

$238.69

The Directa Ceramir CAD/CAM Blocks are available as T-BLOCK, C-BLOCK and i-BLOCK in various types, size and shades. Available in 12x14x18mm size.

Ceramir CAD/CAM T-BLOCKS are highly translucent blocks that mimic the natural enamel. This universal T-BLOCK can be individually color matched through cementation, which can simply the clinical procedure leading to less inventory stock needed in your practice.

Ceramir CAD/CAM C-BLOCKS are chromatic blocks, which correspond to shades A0, A1, A2 and A3.

Ceramir CAD/CAM i-BLOCKS are used for precise and reliable fabrication of implant supported restorations. They fit precisely onto titanium (Ti-Base) or similar attachments so that the final restoration can be placed the same appointment to save time and cost, and to improve the patient's experience.

In the market today, CAD/CAM BLOCKs range from mainly glass component blocks like feldspathic glass which is highly esthetic but brittle to high strength zirconia blocks that lack esthetics. Composite CAD/CAM BLOCKs on the other hand lack both strength and esthetics but have the flexibility of dentin. In contrast to other CAD/CAM materials, Ceramir CAD/CAM BLOCKs are made up of a single glass phase for excellent esthetics and a little resin component for an ideal modulus of elasticity. The modulus of elasticity, which is similar to dentin, allows for a shock-absorbing effect to reduce tension during masticatory load and provides the patient with a pleasant bite feeling. It is a block for all occasions and has components that give the block the best of both worlds, high esthetics without the brittleness of pure glass matrix.

Ceramir Blocks are compatible with systems of the following providers via the TiBase interface: Alphatec, BIOMET 3i, Dentsply Sirona, Nobel Biocare, Straumann and many others.

What Settings Should I Use?

Ceramir is in the process of working with various software programs to add Ceramir CAD/CAM Blocks to select for millings settings. Until this is done you may select any of the 5 products in the attached that are highlighted in orange/red color and these settings will work well with the Ceramir brand. Please check for software updates for Ceramir being a listed manufacturer brand in the near future.

On Page 2 of the attached PDF, you will find two materials highlighted in red: Coltene Brilliant Crios and GC Cerasmart 270. These settings are compatible with all Ceramir CAD/CAM blocks. Additionally, on Page 3 of the PDF, there are three materials highlighted in red: Vitablocks TriLuxe, Vitablocks TriLuxe Forte, and Vita Enamic. These settings will also work with Ceramir CAD/CAM blocks.

CEREC Primemill Tool Table

Click Below to Watch What Makes Ceramir Special

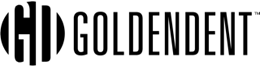

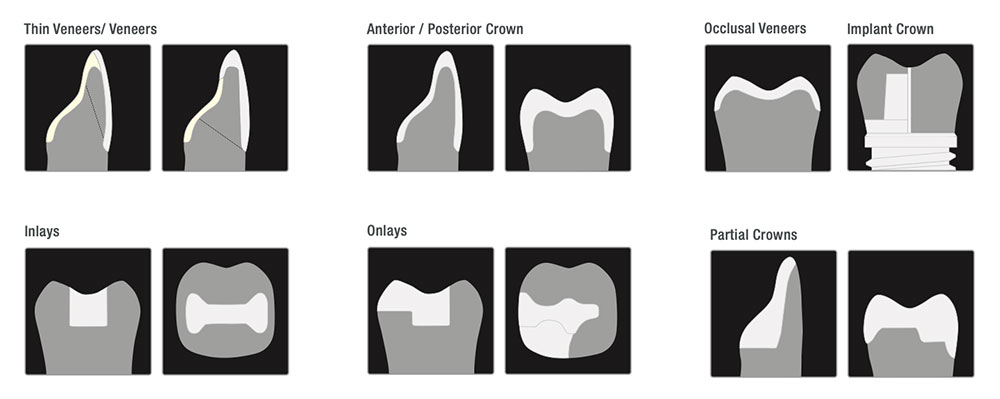

Step-by-Step Guide

Indications for Use

Frequently Asked Questions (FAQ) for Ceramir CAD/CAM Blocks

Scientific Compendium

Clinical Overview of Ceramir by Dr. Marco Tudts

Clinical Overview of Ceramir by Stephan Lampl

Instructions for Use

Ceramir CAD/CAM T-BLOCKS are highly translucent blocks that mimic the natural enamel. This universal T-BLOCK can be individually color matched through cementation, which can simply the clinical procedure leading to less inventory stock needed in your practice.

Ceramir CAD/CAM C-BLOCKS are chromatic blocks, which correspond to shades A0, A1, A2 and A3.

Ceramir CAD/CAM i-BLOCKS are used for precise and reliable fabrication of implant supported restorations. They fit precisely onto titanium (Ti-Base) or similar attachments so that the final restoration can be placed the same appointment to save time and cost, and to improve the patient's experience.

In the market today, CAD/CAM BLOCKs range from mainly glass component blocks like feldspathic glass which is highly esthetic but brittle to high strength zirconia blocks that lack esthetics. Composite CAD/CAM BLOCKs on the other hand lack both strength and esthetics but have the flexibility of dentin. In contrast to other CAD/CAM materials, Ceramir CAD/CAM BLOCKs are made up of a single glass phase for excellent esthetics and a little resin component for an ideal modulus of elasticity. The modulus of elasticity, which is similar to dentin, allows for a shock-absorbing effect to reduce tension during masticatory load and provides the patient with a pleasant bite feeling. It is a block for all occasions and has components that give the block the best of both worlds, high esthetics without the brittleness of pure glass matrix.

Ceramir Blocks are compatible with systems of the following providers via the TiBase interface: Alphatec, BIOMET 3i, Dentsply Sirona, Nobel Biocare, Straumann and many others.

What Settings Should I Use?

Ceramir is in the process of working with various software programs to add Ceramir CAD/CAM Blocks to select for millings settings. Until this is done you may select any of the 5 products in the attached that are highlighted in orange/red color and these settings will work well with the Ceramir brand. Please check for software updates for Ceramir being a listed manufacturer brand in the near future.

On Page 2 of the attached PDF, you will find two materials highlighted in red: Coltene Brilliant Crios and GC Cerasmart 270. These settings are compatible with all Ceramir CAD/CAM blocks. Additionally, on Page 3 of the PDF, there are three materials highlighted in red: Vitablocks TriLuxe, Vitablocks TriLuxe Forte, and Vita Enamic. These settings will also work with Ceramir CAD/CAM blocks.

CEREC Primemill Tool Table

Click Below to Watch What Makes Ceramir Special

Step-by-Step Guide

Indications for Use

Frequently Asked Questions (FAQ) for Ceramir CAD/CAM Blocks

A: The ultrafine sintered glass microstructure of Directa Ceramir blocks is the key. This unique structure, achieved through a precise manufacturing process, results in a dense and homogenous material. This density contributes to high flexural strength, making the restorations durable and resistant to fracture. The smooth surface resulting from the fine microstructure also contributes to a permanent high gloss, creating a natural and esthetic appearance that resists staining.

A: No, Directa Ceramir blocks are designed for efficient milling. Their consistent density and homogenous structure allow for smooth and predictable milling, reducing the time required for the milling process compared to some other materials. This saves valuable time for both the dental practice and the lab.

A: No, the material composition of Directa Ceramir blocks is formulated to be gentle on milling burs. While they possess high strength for durable restorations, their controlled hardness minimizes wear and tear on the burs during the milling process. This helps prolong the lifespan of the burs, reducing replacement costs.

A: No, a significant advantage of Directa Ceramir blocks is that they do not require additional firing. This eliminates a time-consuming step in the restoration process. After milling, the restoration only needs to be polished and cemented. This streamlining significantly reduces chairside or lab time and simplifies the workflow.

A: No, Directa Ceramir restorations are designed for a simple and reliable cementation procedure. The material's surface characteristics allow for strong bonding with commonly used dental cements. This, combined with proper bonding protocols, ensures a proven perfect seal, minimizing the risk of microleakage and secondary caries, leading to long-lasting restorations.

A: Directa Ceramir blocks contribute to cost savings in several ways. The shorter milling time reduces chairside or lab time, leading to increased efficiency. The reduced wear on milling burs lowers replacement costs. And the elimination of the firing process saves both time and energy. These factors combine to make Directa Ceramir a cost-effective restorative option.

A: Yes, Directa Ceramir blocks are designed to be both biomechanical and biocompatible. Biocompatibility means the material is safe to use within the oral environment and does not cause adverse reactions with the surrounding tissues. The biomechanical properties of the material, such as its strength and elasticity, closely mimic natural tooth structure, contributing to the long-term success of the restoration.

A: Directa Ceramir restorations offer an esthetically superior, life-like appearance due to several factors. The ultrafine microstructure allows for excellent light transmission and reflection, mimicking the optical properties of natural teeth. The material is available in a range of shades to match the patient's existing dentition. The high polish achievable with these blocks further enhances the natural appearance, resulting in beautiful and seamless restorations.

A: Yes, if needed, Directa Ceramir restorations can be easily fine-tuned or repaired chairside using standard dental instruments and polishing techniques. This offers flexibility and convenience for the dentist, allowing for minor adjustments or repairs without the need to remake the entire restoration.

A: Ceramir T-BLOCK or Translucent Blocks are highly translucent CAD/CAM BLOCKs that mimic the natural enamel in optical properties. Restorations milled from these blocks have a more life-like appearance resembling the natural tooth. The luminance of the edelweiss T-BLOCK matches that of the natural enamel blending the final restoration to its surrounding giving an excellent bio-harmonious and highly esthetic outcome.

For a highly aesthetic case the Ceramir T-block will be suited as the underlying dentin shade and together with a shaded composite cement will make it possible to adapt the colour of the final restoration to perfection.

For a highly aesthetic case the Ceramir T-block will be suited as the underlying dentin shade and together with a shaded composite cement will make it possible to adapt the colour of the final restoration to perfection.

A:

Ceramir C-BLOCK or Chroma Blocks are highly chromatic CAD/CAM BLOCKs that correspond to shades A0, A1, A2 and A3. These blocks have higher chroma values and can easily blend with their surroundings when the restoration is correctly matched.

A:

Ceramir i-BLOCKs are CAD/CAM BLOCKs used for precise and reliable fabrication of implant-supported restorations. Precision manufacturing processes guarantee the new Ceramir i-BLOCKs fit precisely onto Titanium Base (Ti-Base or similar attachments) so that the final restoration can be placed in the same appointment, reducing treatment sessions and improving the patient experience.

A:

For a highly esthetic case, the Ceramir T-BLOCK will be best suited. The T-BLOCKs are highly translucent blocks that mimic the natural enamel in optical properties and tend to adapt better to their surroundings due to increased light translucence. This leads to a better blend-in effect, which is desirable for a highly esthetic outcome.

The underlying dentin shade can then be duplicated using various resin composite/cement shades. The final shade matching of the restoration can be adjusted by using the appropriate composite shades. This can be further individualized by varying the composite shades according to cervical and incisal color variations in the natural tooth.

The underlying dentin shade can then be duplicated using various resin composite/cement shades. The final shade matching of the restoration can be adjusted by using the appropriate composite shades. This can be further individualized by varying the composite shades according to cervical and incisal color variations in the natural tooth.

A:

The C-BLOCKs are high chromacity blocks and correspond to Shades A0, A1, A2 and A3. For simplicity of use these blocks can be easily matched to the tooth shade. They are better suited for covering discolorations and ideal for elderly patients with a reduced enamel content. Both the T-BLOCKs and the C-BLOCKs can be individualized for optimum esthetics using internal or external characterizations.

A:

The Ceramir i-BLOCK can be easily integrated into your practice’s digital workflow. Our new Ceramir i-BLOCKs fit perfectly with TiBase solution (or equivalent). Precision manufacturing processes ensures a precise fit. It can be used as screw retained single abutment crowns as well as for mesostructured and crown.

A:

It is compatible with systems of the following providers via the TiBase interface: Alphatec, BIOMET 3i, Dentsply Sirona, Nobel Biocare, Straumann and many others

A:

Ceramir dentistry presents a breakthrough in the fabrication of CAD/CAM materials. Through a process of laser sintering and vitrification, Ceramir dentistry has developed state of the art CAD/CAM BLOCKs. Through this process, the glass particles are fused, and the finished product consists of a single hybrid glass-phase embedded in a resin matrix. As a result, the esthetic properties are like that of feldspathic glass ceramic without having the brittleness of pure ceramics

A:

The glassy matrix defines the esthetic properties of the material. The higher the glass content, the greater the translucency is, which will work best to imitate the properties of enamel and dentin. This glassy matrix permits the diffusion of light for translucency. The glass component also allows for adhesive bonding to tooth structure, which is critical to the restoration’s long-term retention and durability.

A:

No, through a controlled manufacturing process, Ceramir dentistry has retained a small portion of resin component that provides elasticity to the block. The modulus of elasticity of the block is 20 GPa which is very similar to that of dentin. In this way the Ceramir BLOCK has the esthetics of that of feldspathic glass without having the brittleness of pure ceramics. It maintains its flexibility similar to dentin giving it the best of both worlds, flexibility and esthetics in one block

A:

Restorations milled from Ceramir CAD/CAM BLOCKs offer exceptional mechanical properties. High flexural strength provides for resistant restorations. The modulus of elasticity, which is similar to dentin (20 GPa), allows for a shock-absorbing effect to reduce tension during masticatory load and provides the patient with a pleasant bite feeling. In addition, Ceramir CAD/CAM restorations are highly abrasion resistant. At the same time the wear-resistance of the material proves to be especially kinder on the antagonist teeth causing no abrasion to the opposing enamel in comparison to other ceramic restorations.

| Flexural strength MPa Biaxial | Flexural strength MPa Three point | Compressive Strength MPa | Flexural Modulus e-modulus | Surface hardness |

| 320 MPa | 200 MPa | 550 MPa | 20 GPa | 100 HV |

A:

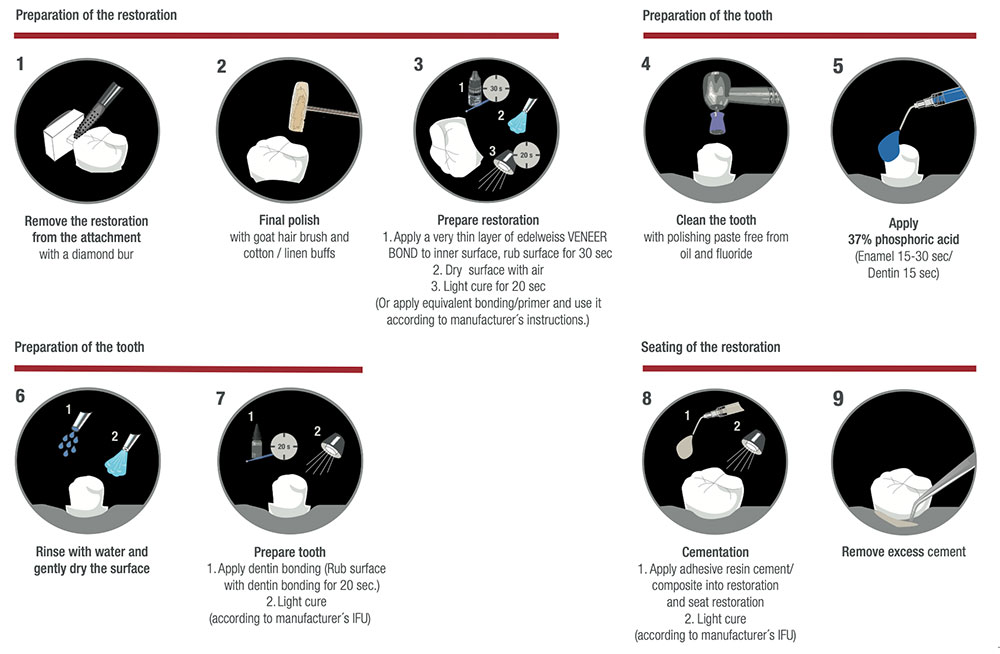

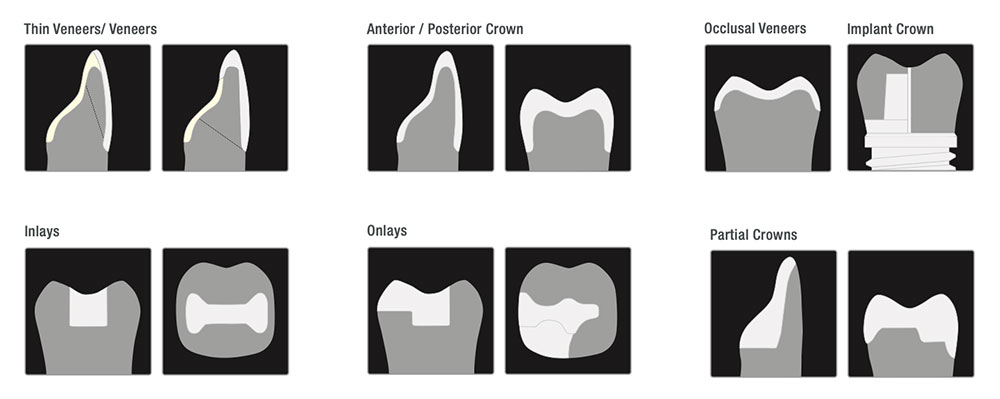

- Anterior and posterior single crowns

- Partial crowns

- Implant supported single crowns.

- Inlays and Onlays

- Veneers

A:

- Esthetically superior, lifelike appearance: Combines the esthetics of feldspathic glass and the strength of ceramics in a single hybrid glass for natural translucency and high strength.

- Flexible clinical color match: Ceramir BLOCKs are translucent to mimic the natural enamel. The final color match is adjusted through use of corresponding composite cement shade. Ceramir BLOCKs are also available in Vita shades A0, A1, A2, A3.

- Custom internal characterizations according to patients needs with Ceramir Opaque White, EFFECT SHADEs Ice and Blue.

- Ultrafine glass microstructure combines high strength with permanent high gloss.

- Proven high compressive strength.

- Biocompatible. Zinc oxide nanoparticles provide built-in antibacterial properties preventing any plaque accumulation on the surface of the material. Fluoride enables possible hydroxyapatite regeneration if required. The addition of ZnO and F¯ is unique to the Ceramir CAD/CAM BLOCKs.

- Simple cementation procedure with proven perfect seal and absence of microleakage.

- Shorter milling times, no additional firing required, simply polish and cement.

- Cost saving. Faster processing time reduces chairside times.

- Kinder to the milling burs. Because of the higher pure glass content and resin portion together with the absence of any ceramic component the milling process is much shorter, and the milling burs tend to last longer. It is possible to be able to mill more restorations from a single milling bur.

A:

In the market today, CAD/CAM BLOCKs range from mainly glass component blocks like feldspathic glass which is highly esthetic but brittle to high strength zirconia blocks that lack esthetics. Composite CAD/CAM BLOCKs on the other hand lack both strength and esthetics but have the flexibility of dentin. In contrast to other CAD/CAM materials, Ceramir CAD/CAM BLOCKs are made up of a single glass phase for excellent esthetics and a little resin component for an ideal modulus of elasticity. The modulus of elasticity, which is similar to dentin, allows for a shock-absorbing effect to reduce tension during masticatory load and provides the patient with a pleasant bite feeling. It is a block for all occasions and has components that give the block the best of both worlds, high esthetics without the brittleness of pure glass matrix.

A:

Minimum thickness at walls should be at least 0.5 mm. For veneers, minimal cervical thickness of at least 0.3 mm. Prepare margins with chamfer or rounded shoulder preparation. For inlays and onlays, all internal edges and angles should be rounded. Avoid having margins in direct occlusal contact with the opposing tooth. The minimum thickness of the restoration should be 1.5 mm in pit and fissure areas and 1.5 mm in cusp areas.

A:

Diamond burs are recommended during the milling process. To select the correct burs, it is suggested to refer to the device manufacturer’s recommendation

A:

Ceramir recommends using a wet grinding/milling process to achieve best possible results.

A: Ceramir CAD/CAM is available as a block 12 x 14 x 18 mm and is compatible with most CAD/CAM milling devices. The block size and milling parameters are standard parameters and are available in all software settings of the CAD/CAM systems. Select a program used for hybrid blocks.

A: All excessive cement must be removed. Occlusal contacts can be adjusted with a suitable grinding instrument, also interproximal areas need to be cleared of any excess cement using a finishing & polishing strip- we recommend you use the ContacEZ finishing strips. Final polishing of the restoration is achieved using a cotton/linen buff for a high gloss finish.

A: We recommend that you use an adhesive resin based shaded composite or composite cement for the cementation. Follow the instructions for use for the cement manufacturer.

For more detailed information see Ceramir CAD/CAM BLOCKS IFU.

For more detailed information see Ceramir CAD/CAM BLOCKS IFU.

A: After the try on of the restoration is confirmed, the restoration must be treated with a hydrophobic primer prior to cementation. We recommend that you use Edelweiss Veneer bond. Other bonding materials can be used, for more alternatives, brands- see Ceramir CAD/CAM BLOCKS IFU.

Apply a thin layer of or Edelweiss Veneer bond onto the surface of the restoration, rub the surface for 20 seconds. Gently airdry the surface with an oil free air.

Apply a thin layer of or Edelweiss Veneer bond onto the surface of the restoration, rub the surface for 20 seconds. Gently airdry the surface with an oil free air.

A:

Prepare the tooth using an adhesive composite bonding- follow the instructions for use from the manufacturer.

A: Yes, the Ceramir CAD/CAM restorations can be both modified and repaired without affecting the properties of the material. If a reparation inside the mouth is necessary, the surface of the restoration shall be roughened with a diamond bur. Step two, apply a hydrophobic bonding to the surface of the restoration- we recommend the Edelweiss Veneer bond. Also, other bonding materials can be used- for more detailed information see the IFU for Ceramir CAD CAM BLOCKS.

Always follow the IFU from the manufacturer of the bonding material.

Apply a resin-based light cured composite to the area that needs to be repaired. Final polishing of the composite is done by following the Instructions for use from the manufacturer.

Apply a resin-based light cured composite to the area that needs to be repaired. Final polishing of the composite is done by following the Instructions for use from the manufacturer.

A: It is recommended for optimal performance, to be stored at room temperature away from direct sunlight and high humidity.

Scientific Compendium

Clinical Overview of Ceramir by Dr. Marco Tudts

Clinical Overview of Ceramir by Stephan Lampl

Instructions for Use